When deciding on a type of crane, it is vital to understand the differences between overhead cranes and a bridge crane. Overhead cranes have double girders, while bridge cranes perform one task on a vertical plane. For example, a bridge crane has a bottom-running trolley, while an overhead crane has a double girder design.

In construction, the two most common crane types are the bridge crane and the overhead crane. Both of these very different crane types are used to lift heavy loads and place them in an optimal position for construction. Each type has its own unique set of advantages and disadvantages, and choosing one over the other will depend on your individual project requirements.

The primary difference between bridge cranes and overhead cranes is the location of their hoist. An overhead crane hoist is located directly above the cab and bridge cranes have their hoists located at either end of a fixed or pivoting support structure known as a “bridge”. Let’s take a look at some other key differences between these two popular cranes.

The bottom running trolley

A bottom-running trolley is a bridge crane with wheels that run along the bottom of the bridge girder. They are used for situations with insufficient headroom for a top-running crane. In addition, bottom-running cranes have lower hook heights than top-running cranes, which may limit the size of lifts.

Its design is similar to a regular bridge crane but is positioned between the bridge girder and the side wall. The load block is supported by a web plate attached to the lower flange. A connecting member connects the web plate to the upper and lower flanges.

Hoists perform a single task on a vertical plane.

Hoists are mechanical devices that raise and lower loads from one level to another. Unlike cranes, which move objects up and down on a horizontal plane, hoists move things in a vertical plane. They move objects up and down using a chain or wire rope.

Hoists are more efficient than other lifting systems because they require less effort. They have a lower height and higher lifting capacity than cranes and are usually equipped with a load limiter. Electric hoists can be used in conjunction with a winching system for various tasks.

A double girder design may be necessary for overhead cranes

A double girder design may be necessary for your overhead cranes if you need an enormous lifting capacity and a wide span. However, you may want to consider lighter-duty options. These are not as expensive and do not require abnormal capacities or spans. This makes them a cheaper option for specific applications.

Double girder overhead cranes have two girders, a pair of end trucks, and a trolley hoist assembly. The hoist travels on rails that are mounted on the bridge girders.

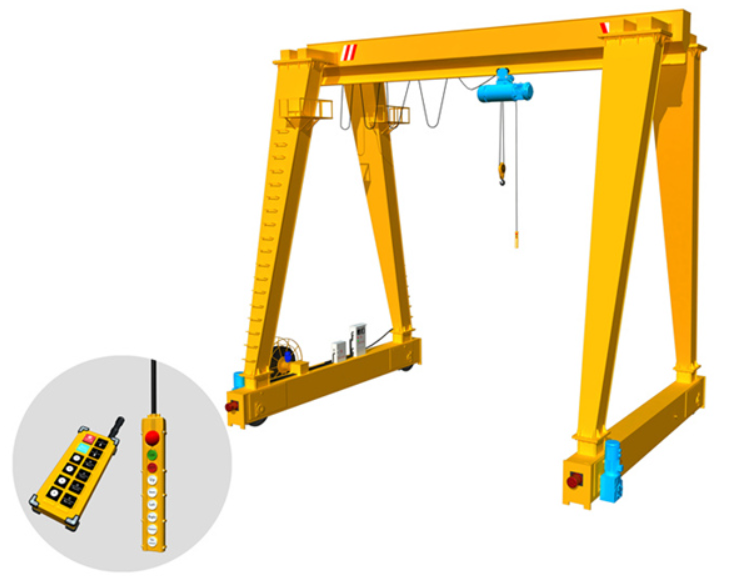

Gantry cranes are more flexible and versatile than bridge cranes

These cranes are made of a girder, running mechanism and lifting device. The cab is on top of the girders and controls the lifting mechanism. It can lift from five tons to one hundred tons. Gantry cranes come in a variety of configurations. They can be semi-rigged or two-legged.

They are widely used for industrial manufacturing. The mobility and flexibility of these machines make them the only choice for many applications. They are perfect for applications that require confined space access, fall protection and a wide range of lifting capacities. In addition, they are often on castors so that they can service the entire work site.

Safety of an overhead crane

When working with an overhead crane, there are several important safety considerations you should keep in mind. Among them is the proximity of the crane to power lines. The crane must be kept at least ten feet from power lines, and the operator must follow specific rules and regulations to ensure a safe work area.

Operators of overhead cranes must have specialized training and certification. They must also understand the equipment, which includes the proper use of standard hand signals. In addition, they should be knowledgeable about the materials beneath the crane and their limits and loads.

Alden Picarella writes about rehabilitation, second chances, and support systems that help individuals rebuild their lives.